Elevance / Anthem Case Study

THE PROJECT

SCOPE: Replace the pneumatic controls with Automated Logic building automation controls for the whole building.

BUILDING INFO: The building is an 8-story, 456,652 SF office building in St. Louis, MO.

HVAC SYSTEM: The office space is served by (7) AHUs, (3) RTU, (3) chillers, (8) water pumps, (4) cooling tower fans, (464) FTUs, and (177) VAVs. There is over 600 HP of AHU fan motors that provide the air flow needs of the building. The chiller plant has a total of 1,500 Tons of cooling capacity, with over 230 HP of water pumping capacity.

The data center space is cooled by Liebert CRAC units with a dedicated chiller.

- INSTALLATION: 2014 - 2019

- PROJECT COST: $1,635,000

- AMEREN INCENTIVE: $402,380

IMPROVEMENTS

The building has some office areas that require 24/7/365 operation. Most of the building is occupied by a variety of tenants with varying schedules. The same (4) AHUs and (3) RTUs serve all of these spaces.

Proper scheduling of the building with pneumatic controls was nearly impossible, but with the new building automation system controls the zones would be grouped by tenant and scheduled based upon occupancy. The AHU’s and RTU’s could also take advantage of resets for the discharge air temperature and static pressure reset that allow the equipment to utilized feedback from the building to determine operation. This saves energy and improves comfort.

Lastly, the Automated Logic Chilled Water System Optimizer was installed. The Optimizer resets the chilled water and condenser water setpoints to maximize energy efficiency.

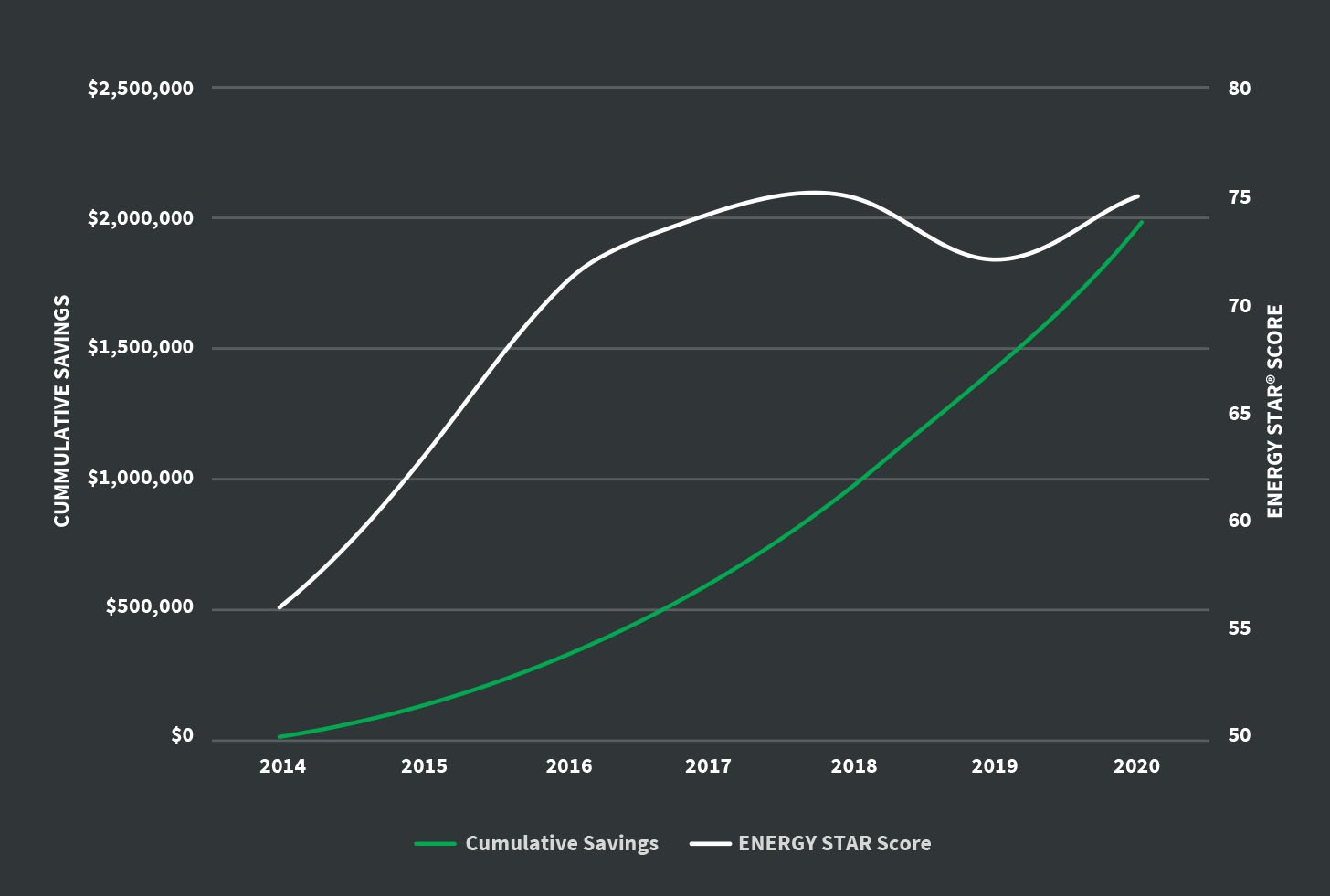

THE RESULTS

2.9 YEARS

$425,000 or 25%

The pre-project ENERGY STAR® score was 56 with a Site EUI of 175.6 kBtu/ft2. As of January 2021, the ENERGY STAR® score has climbed to 75 with a site EUI of 118.4 kBtu/ft2. That is a reduction of 32.6% for the site EUI.

This has been a reduction in total greenhouse gas emission’s reduction of over 3,483 metric tons of CO2e. Per the EPA this is a one-year equivalent of greenhouse gas emissions from 752 passenger vehicles driven, or 8,642,68 miles driven, or CO2 emissions from 402 homes electricity.

Also, there was a significant reduction in comfort complaints after the upgrade were complete. This would indicate a higher level of comfort in the building, which results in higher productivity by the occupants. These are harder measures to identify and track, but very evident by the reduced comfort complaint calls.

Ready to take control of your energy management and unlock the potential for savings and efficiency?

Connect with an Automatic Controls representative today to take the first step.